DESCRIPTION

Flat Spiral Spring (Strip Spring)

Flat Spiral Spring (Strip Spring)

Flat spiral springs are produced from formed strip material, which is pre-stressed to form a tight coil. These springs can be fully or partially unwound. Due to their ability to exert a constant force over their deflection range, these springs are used in linear motion applications.

SPRING TECHNICAL DATA

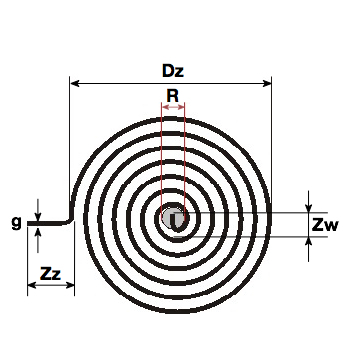

Specification:

[Dz] - Outer diameter of the spring

[R] - Mandrel diameter

[g] - Strip thickness

[a] - Strip width

[Lt] - Developed length of the strip

Spring Material:

- Hardenable spring steel - cold-rolled

- Hardenable spring steel - hot-rolled

- Stainless spring steel

Material Type:

- With standard edges

- With rounded edges

Advanced Technological Solutions

Known primarily from clock mechanisms, they also find application in many other industries. Flat spiral springs (strip springs) are components that ensure high performance and reliability. They are found in many designs utilizing linear motion, as they are components that exert force over a range of deflection.

These remarkable components, known for applications such as precision mechanics, meet the needs of the most demanding projects. Their unique design and high-quality workmanship guarantee excellent performance and long-term reliability. Every flat spiral strip spring is a key to innovation in many industries.

These remarkable components, known for applications such as precision mechanics, meet the needs of the most demanding projects. Their unique design and high-quality workmanship guarantee excellent performance and long-term reliability. Every flat spiral strip spring is a key to innovation in many industries.

Flat Spiral Springs - Advantages

Utilizing these components in your designs will not only enhance their efficiency but also ensure seamless operation. Thanks to its flat form, every flat spiral spring (strip) allows for space savings while offering high operating force and precision of movement. As we mentioned earlier, in the past, these components were mainly used in mechanical clocks. Currently, they are more often used in toy drives or devices utilizing the principles of precision mechanics.

A key aspect that distinguishes flat spiral springs from other solutions is their unparalleled strength and elasticity. Thanks to the use of formed strip material and adapted production technology, these components can withstand extreme loads while retaining their properties for a long time. Furthermore, their unique design allows for perfect adaptation to the specific requirements of any project, providing an optimal solution for every challenge. Discover the potential hidden in every flat spiral strip spring and let your projects reach a new dimension of efficiency.

A key aspect that distinguishes flat spiral springs from other solutions is their unparalleled strength and elasticity. Thanks to the use of formed strip material and adapted production technology, these components can withstand extreme loads while retaining their properties for a long time. Furthermore, their unique design allows for perfect adaptation to the specific requirements of any project, providing an optimal solution for every challenge. Discover the potential hidden in every flat spiral strip spring and let your projects reach a new dimension of efficiency.

Whether you require single units or thousands of pieces, it makes no difference. All our springs are manufactured with the highest precision according to your individual needs.

Do not hesitate! Contact us using the form and submit a request for quotation to learn more!